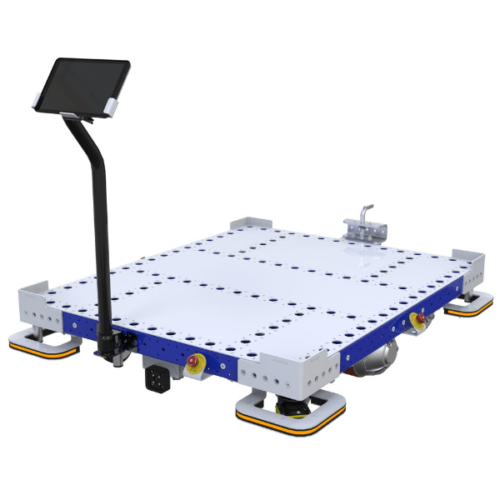

Freight 100

Designed to be highly extensible and versatile, our fully autonomous Freight100 Base is a safe and cost-effective solution to accelerate the development of automated products and solutions for a wide range of applications. Integrators and software partners can build upon the Freight100 Base and leverage Fetch Robotics’ proven hardware and software expertise to quickly bring automated solutions to life.

Here are a few ready-to-order solutions utilizing the Freight100 mobile robot base:

The HMIShelf

HMIShelf provides autonomous transport in virtually any facility. Deploy in just hours and carries a wide range of bins, totes and packages with its fully configurable and customizable shelving system.

- Simple operation with built-in, easily configured touchscreen

- Configurable shelving for various bin, tote, and package sizes

- Reduce associate travel time, increase productivity in low dwell time and high volume environments

The CartConnect

CartConnect robots autonomously pick up and drop off the FetchCarts to any location within facilities with material handling needs.

- Multiple sensors ensure CartConnect safely and efficiently navigates between locations

- Able to work safely alongside people, forklifts, and other material handling equipment

- Transports materials within a facility at a speed of up to 1.5 meters per second

The RollerTop

RollerTop robots autonomously pilot their way to conveyor ends and/or ASRS ends to load and unload totes and bins.

- Automate loading and unloading of totes and bins from conveyors or ASRSs

- Flexibly extend existing conveyor workflows

- Automatically trigger induction or deduction via Fetch Robotics’ FetchCore software

The TagSurveyor

To physically count inventory requires hours of manual work and is often done very infrequently. Tagging assets with RFID immediately improves inventory tracking, increases accuracy, and saves time. With a TagSurveyor solution, you can increase inventory counts and checks from once-a-month to multiple times per day, even in the largest warehouses.

- Three RFID antennas for full single pass coverage

- Precise path and positioning for consistent and maximum tag discovery

- 82 degrees of sensor coverage to reach tagged items even on tall shelving

- Up to 7.6m (25ft) of read range

- 24/7 automated data gathering with autonomous charging

- Powerful data visualization to locate misplaced inventory

- Continuous cycle counting & inventory tracking