- 385-900-7460

- orders@synertechusa.com

- 2520 Rulon White Blvd, STE B, Ogden, UT 84404

Robotic Automation’s Rise In Food and Beverage Manufacturing

The importance of automation has increased in the fast-paced food and beverage processing industry, where quality and efficiency are non-negotiable. The food industry’s use of automation is a matter of necessity, not a trend. Production managers and plant operators continuously search for innovative methods to improve product quality, lower operating expenses, and streamline processes. Robotic automation is becoming a major player out of numerous technologies that have surfaced as game-changers for manufacturing.

The Evolution of Robotics in Food and Beverage

A Historical Perspective

A Historical Perspective

In order to comprehend how robots are affecting the food manufacturing sector, let’s take a quick look back. In the past, producing food and beverages required a lot of labor, with devoted teams of workers directly handling and packaging goods. Although it was impressive to see, it required a lot of work and time. But as automation entered the picture, things started to change.

Conveyor belts and crude assembly lines were the first examples of automation in food and beverage manufacturing. However, it now includes an area where highly developed robotic systems are essential. These robotic systems are precise tools that have the potential to revolutionize the food and beverage manufacturing industry, a far cry from the simple machines of the past. To meet the ever-increasing standards for safe food and beverage production, an increasing number of robots with stainless steel design and food-grade safety are being produced specifically for use in food and beverage production.

Key Drivers of Robotics Adoption

There are various major factors that have contributed to the use of robotics in the food production industry. Efficiency is a critical factor. Robot cells such as palletizers or case packers and other automated systems are able to essentially work nonstop, lifting, stacking, and packing goods with unmatched accuracy. The end result is product that is consistently and accurately prepared for shipping—all with little hiccups or issues.

Applications of Robotics in the Food and Beverage Industry

Now, let’s dive into the practical applications of robotics in food and bev manufacturing:

Raw Materials and Ingredient Automation

There comes a time in the production process when the first raw materials and ingredients must be introduced or injected. As the material is consumed by the production process, this phase is repeated over and over. While it is common for programmable logic controllers, or PLCs, to handle the measuring and weighing of ingredients at this phase, this also can be an excellent use case for robotics because handling such a large volume of raw ingredients can be very taxing for workers. The replenishing of the raw materials must be performed especially quickly if the production line is operating speedily. A robotic picking cell might handle the frequent heavy lifting necessary at the front of the production line.

Automated Processing and Assembly

Depending on the type of food or drink being made, there is typically an assembly-style process in the middle of the line. Robots may be taught to carry out a wide range of these assembly operations, from slicing and mixing to sizing and arranging, to ensure accuracy, speed, and maximizing production lines. Workers’ once mind-numbing and repetitive activities are now swiftly and safely completed by robot cells equipped with end-of-arm tooling that is specific to the products and application at hand. Think of tasks like frozen sandwich stacking and assembly, pastry and cake frosting, or raw meat handling. Robots can be inserted at points like these to reduce bottlenecks and create more efficiency.

Food Safety and Inspection

In food manufacturing, food safety and quality are a must. With the use of cutting-edge vision systems, many leading food and bev manufacturers go above and beyond in quality control, carefully inspecting each product to look for defects, irregularities, and foreign objects. The result is a level of quality control and efficiency that can be difficult for workers who take time to develop an eye for imperfections and can lose focus as their shift goes by.

Automated Labeling Solutions

Automated Labeling Solutions

The application of labeling is great for automation – whether it be small labels on food and beverage containers or larger batch stickers on the shipping cases and pallets. Facilities producing massive numbers of products can save a lot of time and money by implementing precision robotic label application instead of slow and inconsistent manual labeling.

Robotic Case Packing

After a product has been made and packaged, it needs to be prepared for shipment. Robotic case packers can seamlessly integrate into the packaging processes, placing products with precision into very specific arrangements. From packaged candies to cheeses to egg cartons, there are ways to robotically pick and pack a variety of foods and beverages into their shipping cases.

Robot Palletizing and Stacking

One of the final steps in the production line, yet most labor intensive, is the stacking and palletizing of packed cases. This seemingly never-ending task can lead to worker back injuries and it is completely dependent on having a strong, reliable workforce. Robotic palletizing systems are very popular and make a lot of sense in facilities that want to scale and become safer and more efficient.

Benefits of Robotic Automation in Food Manufacturing

The adoption of robotic automation in food manufacturing yields several significant benefits:

Increased Efficiency and Productivity

Efficiency in food manufacturing is a make-or-break factor in staying competitive. Automation and robotic systems can maintain or even increase the speed of production – ensuring that your products consistently meet market demands.

Improved Product Quality

Consistency is the hallmark of quality. Custom robotic systems ensure that each product leaving the manufacturing facility meets the highest quality standards, maintaining the reputation and brand integrity. Some of the human-error in production gets reduced through automation such as the amount of scrap or incorrect packaging or labeling.

Cost Savings and Reduced Labor Dependency

Robotic automation such as palletizers and case packers are not just efficient; they are also cost-effective. Today’s world is experiencing unprecedented labor shortages, especially in the manufacturing sector. By reducing labor dependency and optimizing production processes through industrial automation, operational costs decrease significantly. This is the recipe for a high return on investment for companies needing to scale while enduring the unstable labor market we find ourselves in.

Enhanced Food Safety and Compliance

Compliance with safety and hygiene standards is crucial. Robotic systems excel in this aspect, reducing the risk of contamination and handling products with the utmost care. There are measures in designing a robot cell that can reduce risk for contamination and allow for frequent cleanings of the robot’s tooling which interacts with the food and beverage products.

Case Studies: Real-Life Examples of Robotic Success

Every industry is seeing a demand for the implementation of robotics and automated work cells. SynerTech Automation has been able to work in a variety of these industries. One industry where there has been a rise in robotics is agriculture. Specifically handling the packaging of the food products once they’ve been grown or produced.

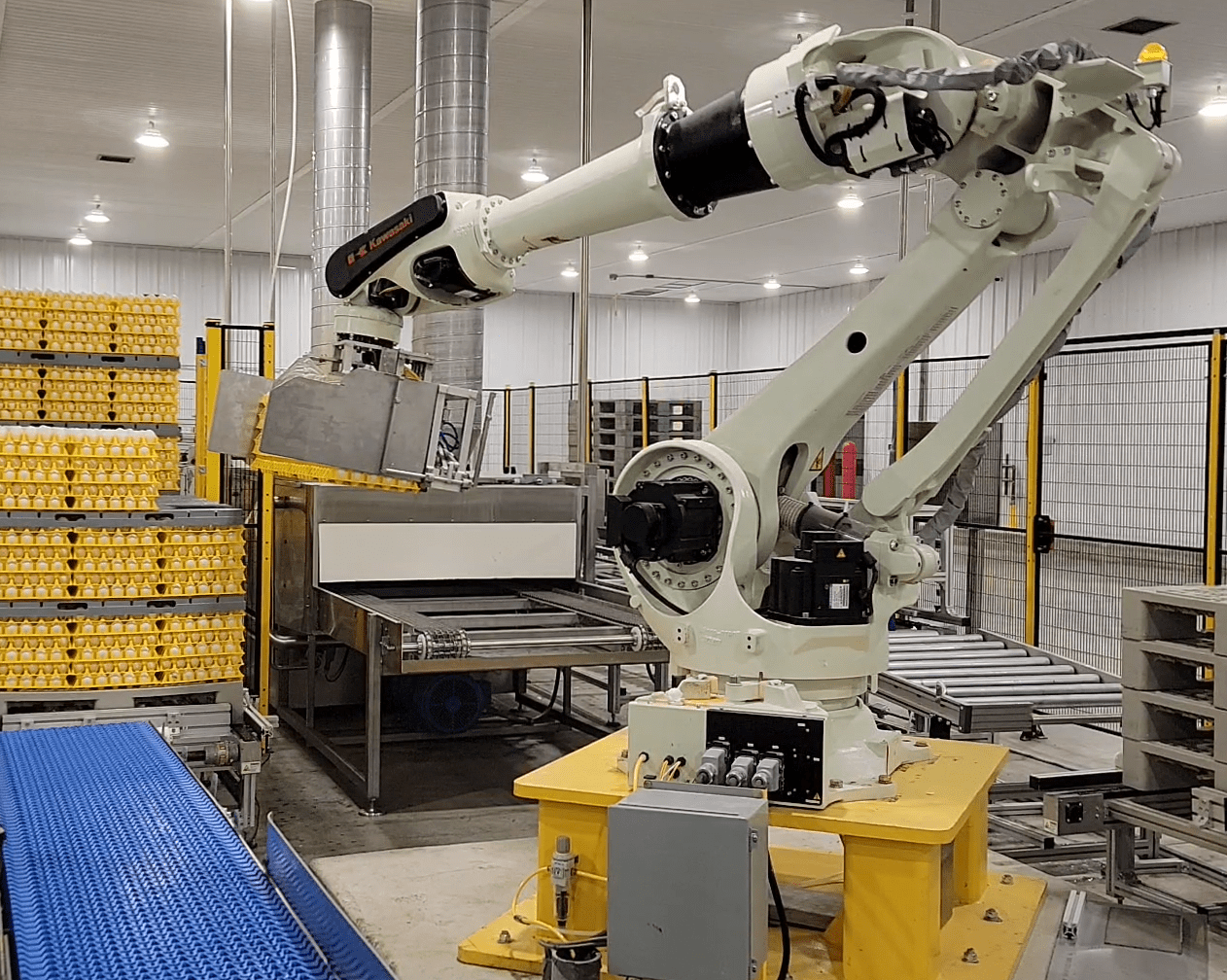

Eggs for example need to be put into cartons, and those cartons need to be packed into cases, and then those cases need to be stacked and palletized for shipment. These are all very labor-intensive stages of the production process. SynerTech Automation has worked with many of these egg producers to implement robotic palletizers at the end of their production lines. This allows the farms to allocate their shrinking work force to other areas of their facility and not risk injuries in these heavy lifting areas of their facility.

Case packing applications in these egg farms is where SynerTech is focusing next. Designs and concepts are already in the works for custom robot case packers.

Other sectors inside the food and beverage industry have reached out to SynerTech Automation for their custom automation and robotic solutions. Some examples include: Pet food and treats, milk and fruit juice packers, meat processors, freeze-dried foods and drink powders, just to name a few.

Conclusion

In the ever-evolving landscape of food and beverage manufacturing, automation is not just a choice; it’s a strategic advantage. SynerTech Automation’s custom robotic solutions are the secret ingredient that empowers food and bev manufacturers to meet rising demands, ensure consistent quality, and stay on the cutting edge. As technology continues to advance, the future of food manufacturing is bright and full of possibilities.

Call to Action

Are you ready to elevate your food manufacturing operations? Contact SynerTech Automation today to see how we can help you improve your processes through robotic automation and discover how automation can transform your operations.

Request More

Information

Reach out if you have any questions about our products, our services, or just need a quick price quote. We are ready to help!

- 2520 N Rulon White Blvd, STE B, Ogden, UT 84404

- orders@synertechusa.com

- 385-900-7460